One-Stop-Shop

Contract Manufacturing

Contract manufacturing, franchised distribution, BOM management, component and system level test all under one roof.

We are redefining the meaning of distribution in our industry with value add, test and assembly services now available in-house at Spirit Electronics.

Plus, we now offer heavy copper inlay PCBs that provide superior heat dissipation and improve product performance and lifespan (up to 6 layers and 3.5mm thickness).

These and more exciting capabilities are available at Spirit Electronics in our expanded 16,000sf Phoenix, AZ, facility with 5,300sf dedicated to board assembly.

Contact us today to discuss your possibilities with Spirit.

Episode 9: Leading with Quality in Contract Manufacturing

Listen in on this Spirit: Behind the Screen podcast episode as Tracey Latham talks with Marti McCurdy about contract manufacturing; quality production and equipment; her team and experience, and manufacturing tech in Arizona and the US.

Capabilities & Features

- Leading-edge, proprietary method of robotic re-ball and solder exchange to create leaded solutions.

- Highly accurate and versatile board assembly that can accurately place an 03015 ultra-tiny chip to the industry’s largest FPGA components onto a customers board

- SMT/SMD, thru-hole and mixed technology PCB assemblies and the ability to trace a part all the way down to the reference designator on the board

- PCB sizes from 50mm x 50mm (2″ x 2″) to 810mm L x 480mm W

- Our 10-zone oven will handle most thermally challenging assemblies, especially heavy multi-layered PCBs and aluminum boards for the LED industry.

- Not only is the equipment top-of-the-line, but so is the experienced, expert workforce trained to IPC610 and AS9100 standards.

Tracey Latham, founder & CEO of Latham Industries, named SBA Small Business Person of the Year for Arizona

We are thrilled to share that Tracey Latham, founder and CEO of Latham Industries, LLC and Spirit's contract manufacturing partner, was named the 2022 SBA Arizona Small Business Person of the Year! Latham Industries provides the highest quality printed circuit board (PCB) assembly for aerospace and defense, medical, industrial, communications, and security businesses. With these services all under one roof in our facility, our customers benefit from one-stop supply chain security and full custody control.

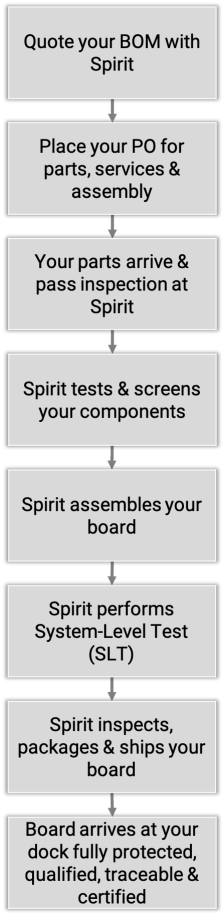

Our Board Assembly Workflow

Our in-house workflow offers full-capability board assembly.

If you’re used to ordering components, inspecting them into your facility, and then sending them back out to your contract manufacturer for assembly, you could be putting your components and your finished board at increased risk of damage from handling and shipping.

Take a moment to consider the additional costs and overhead involved with your current flow. You’ll have to ship the product out, vet your contract manufacturer, audit their processes, and verify their equipment calibration. They may not have the expertise to manage a full counterfeit prevention program for high-reliability applications, and how do you know whether their ESD control is in a safe enough range for the sensitivity of your board?

The cost and risks only rise if your components need up-screening. You add more test providers, more audits, more supply chain management and shipping. And once the board arrives back on your dock, what about system-level testing? It takes you months to go from quote to finished goods, and a delay at any step could set you back weeks.

There is a better way. What if you could go from quote to finished goods, and we took care of all your needs in between?

Spirit can bring all of these services under one link in your supply chain.

As a franchised, authorized distributor/reseller, we quote your entire BOM from industry-leading OEMS with FPGAs, capacitors, oscillators, memory and even our new line of copper inlay boards. We receive and inspect your product, test and up-screen your parts, and now we can pick-and-place the components onto your printed circuit boards. Finally, we perform your system level testing, package and ship the finished board, and it arrives on your dock reliable, with Spirit’s warranty, ready to use.

But how can we guarantee the finished product when the process has so many steps? Do you lose your control and oversight?

Spirit’s experience in the aerospace and defense industry gives us the unique ability to customize our process to your program. Our account representatives meet with you and update you in real time. If there are part failures or setbacks, Spirit’s service gives you immediate visibility and solutions.

Our processes and equipment are controlled under our certified AS9100 quality management system, and we manage traceability and inspection to counterfeit prevention standards. We’ve gone above and beyond the minimum requirements of ESD S20.20 to protect your product during handling. Most importantly, our trained personnel care deeply about your product safety and mission success.

Set up your board assembly program through Spirit Electronics today.